INDUSTRIAL OIL SEPARATORS

- All industrial kitchens

- Hotel kitchens

- Hospital kitchens

- Buffet

- Animal slaughterhouses

- Grocery store

- Restaurants

- Bars

- Cafes

- It meets the requirements of the oil separator standard EN1825.

- The alarm system is a standard function.

- The connection of the inspection shaft is tight.

- It enables easy and complete emptying.

- It is light and easy to install.

- 50-year guarantee.

- Two categories

The wastewater collection is strictly controlled due to the increasingly strict legislation. All separators are equipped with alarm units that control the operation of the separator. Level alarm devices are available as standard in the separators.

By using the rotating cleaning nozzle developed for oil separators, frozen oil can be easily dissolved in the separator. First, HOT WATER is connected to the rotating nozzle without a mains pump using mains pressure.

For above-ground applications, the oil separator should be cleaned from outside the building. When cleaning with Wavin IMUBOX; In order to reach the lowest point of the oil separator, a suction / pressure line with a diameter of DN80 should be used.

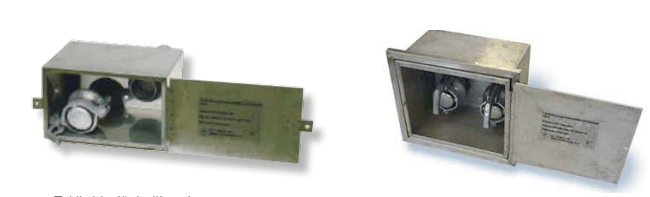

The pipe is used between the IMUBOX wastewater box and the oil separator. The duct connection box with ImuBOX coupling enables the oil separator to be cleaned outside the building. Cleaning should be done at least once a year. There are single and double models.

All Wavin EuroRek oil separators are equipped with alarm units that control the operation of the separator. Level alarm devices are available as standard in the separators. It optionally has thefunction for automatic unloading, cleaning and direct transmission to the service provider as well as an alarm function for the sediment level.

If the separators are tracked automatically, they can be emptied in good time, which minimizes environmental risks and maintenance costs.